Business

Diffusion Bonding & Brazing

Dae Heung Co., Ltd. is an expert in diffusion bonding and vacuum hot-press brazing of aluminum alloys and is engaged in ongoing development and manufacture of a wide range of products with internal shapes.

We manufacture the products you need in the specified shapes and performance criteria to achieve the required performance through the right combination of optimum bonding processes.

Diffusion Bonding of Aluminum Alloys

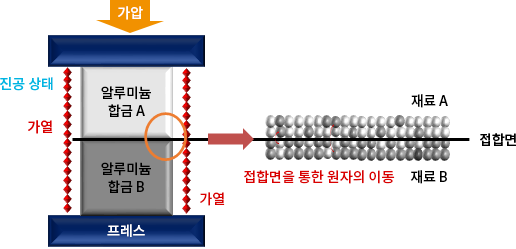

Diffusion bonding is the process in which two heated and pressurized base materials become bonded through atomic diffusion.

Because No fillers are used, unlike other bond methods, bonded surfaces of which properties is similar to the base materials used are achieved.

Diffusion bonding of aluminum alloys can be challenging because the oxide film that forms on base materials interferes with atomic diffusion, but Dae Heung Co., Ltd. has researched and developed methods to overcome this difficulty and is manufacturing diffusion-bonded products of the highest quality.

- Schematic Diagram of Aluminum Alloy Diffusion Bonding Process

Vacuum Hot-press Brazing of Aluminum Alloys

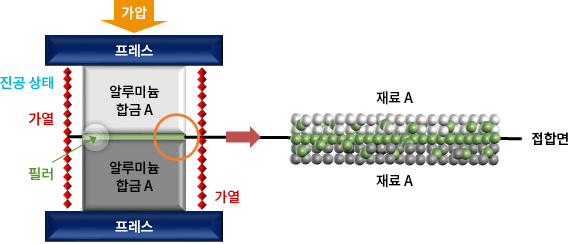

Vacuum brazing involves the use of heat and molten fillers in a vacuum to bond two base materials.

Because the use of fluxes customary with other brazing methods is omitted from vacuum brazing, the resulting benefits of vacuum brazing include no flux cleaning, no corrosion from flux residues, and environment-friendliness.

The attendant outgassing suppresses the generation of pores in bonded parts for outstanding airtightness, and bonded parts of excellent mechanical properties can be achieved, which are two reasons why vacuum brazing is widely used in the aerospace industry.

Dae Heung Co., Ltd. uses a vacuum hot-press in its brazing (vacuum hot-press brazing) to produce flawlessly bonded surfaces as enabled by the application of uniform pressure to base materials.

- Schematic Diagram of Vacuum Hot-press Brazing Process

Diffusion Bonding vs. Vacuum Hot-press Brazing for the Bonding of Aluminum Alloys

| Diffusion bonding | Vacuum hot-press brazing | Note | |

|---|---|---|---|

| Merits |

|

||

| Demerits |

|

||

| Differences | Clean bonded surfaces | Bonded surfaces of internal pipes are prone to R | Use and non-use of fillers |

※ Choose between diffusion bonding and vacuum brazing to achieve the best bonding quality given the shape of a target product.

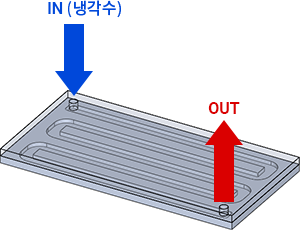

- A Typical Diffusion-bonded Product